Lighting audit in industrial facilities

Increasing energy efficiency requirements and the need to comply with legal regulations mean that lighting audits in industrial facilities have become an important element of energy management strategies. In this article, we will look at the technical and specialist aspects of this process, such as legal regulations, audit scope, measurement methods, benefits and implementation of recommendations.

Legal regulations and normative framework

The lighting audit in industrial facilities is subject to a complex set of legal regulations and standards. The most important documents are the Energy Efficiency Act and the Regulation of the Minister of Infrastructure on energy audit. In addition, industrial facilities must meet lighting standards such as PN-EN 12464-1:2012: Indoor lighting - Part 1: Lighting environment and PN-EN 1838:2013. In addition, there are various industry requirements for lighting in industrial facilities, which depend on the specificity of the activity and working conditions in a given place, e.g.:

- In some industries, especially where visual precision is essential, there are guidelines for minimum lighting levels. This applies to laboratories, manufacturing workshops and assembly operations, for example.

- It is also important to ensure that the lighting is uniform across the workspace to avoid glare, shadows and eye strain for workers. In such cases, standards may specify minimum and maximum differences in lighting levels between different areas.

- Depending on the application, there are preferred lighting colour temperatures, for example: in warehouses or production halls, lighting with a neutral colour temperature may be preferred, ensuring clear visibility of details. In some areas, such as laboratories or exhibition halls, lighting with a colour temperature close to neutral light may be preferred.

- In some work environments, there are requirements for the safety and resistance of lighting fixtures to extreme conditions, such as high humidity, dust or chemical exposure. In such areas, the lighting installation should be suitably protected and meet certain safety standards.

- Increasingly, lighting systems are required to be designed with energy efficiency and minimised electricity consumption in mind. Therefore, industries can set requirements for the energy efficiency class of light sources and the use of energy-saving LED lighting and intelligent lighting control systems.

- All lighting systems must comply with applicable legal regulations and standards regarding safety, energy efficiency and environmental protection. Therefore, they should meet specific standards and have appropriate certificates of compliance.

Audit Scope

A lighting audit in industrial facilities requires a precise definition of the scope of activities. In addition to standard energy efficiency analyses, specific industry requirements and industrial lighting applications must be taken into account, such as lighting intensity, uniformity and color temperature. In particular, the audit may include:

- Analysis of the existing lighting system in terms of the type of light sources, types of luminaires, method of installation and control systems, if present;

- Verification of the electrical infrastructure, i.e. checking the type and condition of the cabling and switchboards, which are an integral element of the lighting infrastructure;

- Measurements of lighting intensity performed using photometers, commonly called luxmeters. They allow for measuring the lighting intensity at various points of the facility in order to assess the level of lighting on the work surface and identify areas that are insufficiently lit or excessively exposed;

- Analysis of the uniformity of lighting in different zones of the facility in order to identify areas with excessive differences in lighting intensity, which can lead to problems with visibility and work comfort;

- Spectral analysis, which allows for the analysis of the spectrum of light emitted by different light sources in order to assess the quality of lighting. It can help identify potential problems such as a deficiency or excess of certain colors;

- Analysis of the energy consumption of the existing lighting system and identification of areas of potential savings through better adaptation to the needs of the facility;

- Assessment of the technical condition of existing luminaires and light sources, including their age, efficiency, and potential damage or operational problems;

- Analysis of the costs associated with the operation of the existing lighting system, including electricity costs, maintenance, replacement of light sources and luminaires, and costs associated with potential failures;

- Modernization recommendations for potential modernizations of the lighting system to improve energy efficiency, lighting quality, and reduce operating costs.

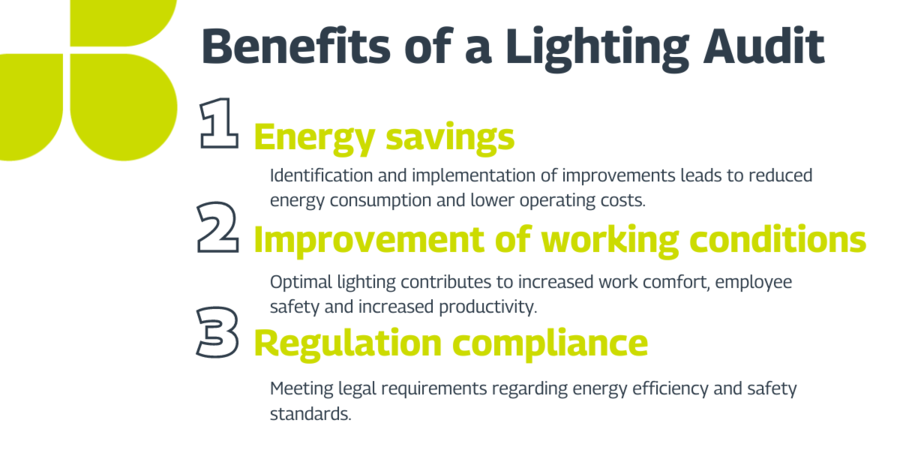

In summary, an industrial lighting audit is a comprehensive process that not only assesses energy efficiency, but also takes into account the specific needs and requirements of different industries. By carefully examining aspects such as lighting intensity, uniformity and color temperature, the audit helps ensure optimal working conditions, compliance with standards and maximizing energy savings. This approach not only supports compliance with legal regulations, but also contributes to improving employee comfort and safety, while promoting sustainable and efficient energy management in enterprises.